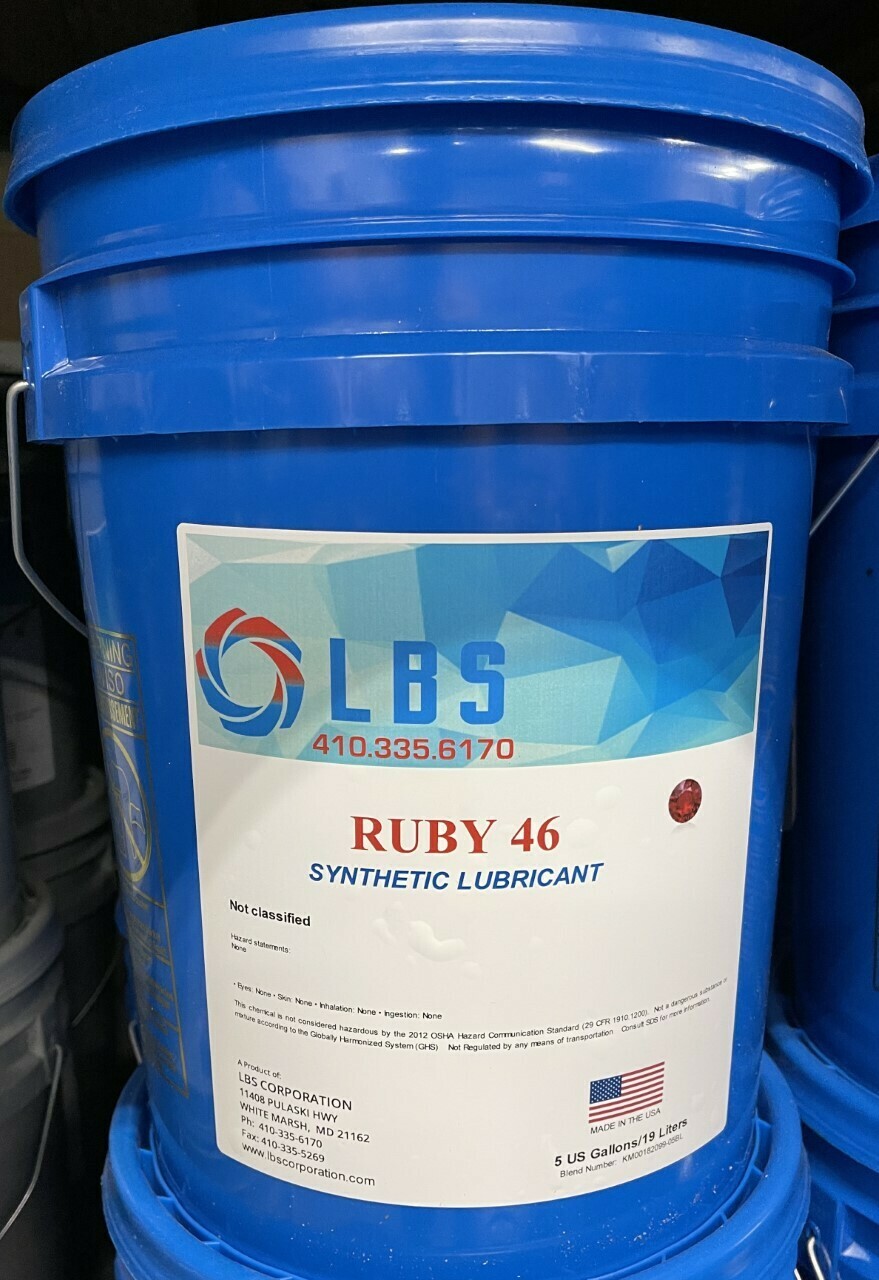

Ruby 46 Rotary Screw Synthetic Lubricant

Product Details

RUBY 46 lubricants are manufactured from the highest quality PAO (polyalphaolefin) base stocks and advanced additive technology. RUBY 46 lubricants are recommended for rotary screw, centrifugal, vane and reciprocating compressors and offer many advantages over petroleum-based lubricants as well as some synthetics -especially where compatibility is an important concern. The SH® Series lubricants have low pour points, high viscosity indices and excellent water demulsibility.

CROSS REFERENCE: ATLAS GA-8K, GARDNER AEON 9000,KAESER S-460, LEROI SSL-46

COMPATIBILITY: The following materials are compatible for use with Diamond 100 lubricants: Epoxy Paint, Celcon, Viton®, High Nitrile Rubber (Buna N, NBR-greater than 36% Acrylonitrile), Medium Nitrile Rubber (Buna N, NBR 30-36% Acrylonitrile), Teflon®, Oil Resistant Alkyd, and Nylon.

Diamond-100 is recommended for use in the following applications:

•Reciprocating compressors

•Rotary vane compressors

•Ball and roller bearings

•Low temperature lubrication

•High temperature lubrication

•General lubrication for applications

•requiring an ISO 100 lubricant

Benefits for your application:

•Low temperature fluidity

•Better thermal conductivity-reduces operating temperature

•Reduced friction – approximately 20% lower coefficient of friction

•High temperature thermal stability will not disassociate under thermal stress

•Greater resistance to mechanical stress will not shear under heavy loads or extreme stress

•Reduced metal-to-metal wear-polar properties provided better metal wetting

•Better demulsibility characteristics-moisture separates readily, providing better rust and corrosion protection

•More energy efficiency

Cross reference : Mattei 8000F2, Gardner Denver Aeon 5000, Ingersoll Rand XL-700